Friday, December 12, 2025

Defence Minister Shri Rajnath Singh today virtually inaugurated 125 major infrastructure projects across the country.

DM Gaurav Kumar Chairs Review on Land Transfer, Arbitration & Highway Widening

District Review on NH-07: Land Transfers & Road-Widening Progress

Under the chairmanship of District Magistrate Gaurav Kumar, a review meeting was held on Thursday with NHIDCL, BRO, and the Rail Vikas Nigam regarding pending cases related to land acquisition, transfer of forest and civil land, and road-widening issues. He directed that all pending land-transfer matters be resolved promptly so that the remaining project works can be completed without delay. He also instructed that swift action be taken in arbitration-related cases as per the decisions already issued. Coordination with the respective tehsils was emphasized to ensure timely disposal of mutation cases.

Regarding the remaining widening work on National Highway-07 between Nandprayag and Chamoli, particularly near Chada (Chamoli), the District Magistrate instructed NHIDCL to coordinate with the SDM to expedite the widening activities. He stressed that traffic must not be disrupted during road-cutting operations. Additionally, he directed the agency to construct protective walls at the dumping zones and level the area to ensure safety.

#Chamoli #NH7 #BadrinathHighway #LandAcquisition #RoadSafety #NHIDCL #BRO

Thursday, April 17, 2025

Break Through Done at Silkyara Tunnel :

Tuesday, March 4, 2025

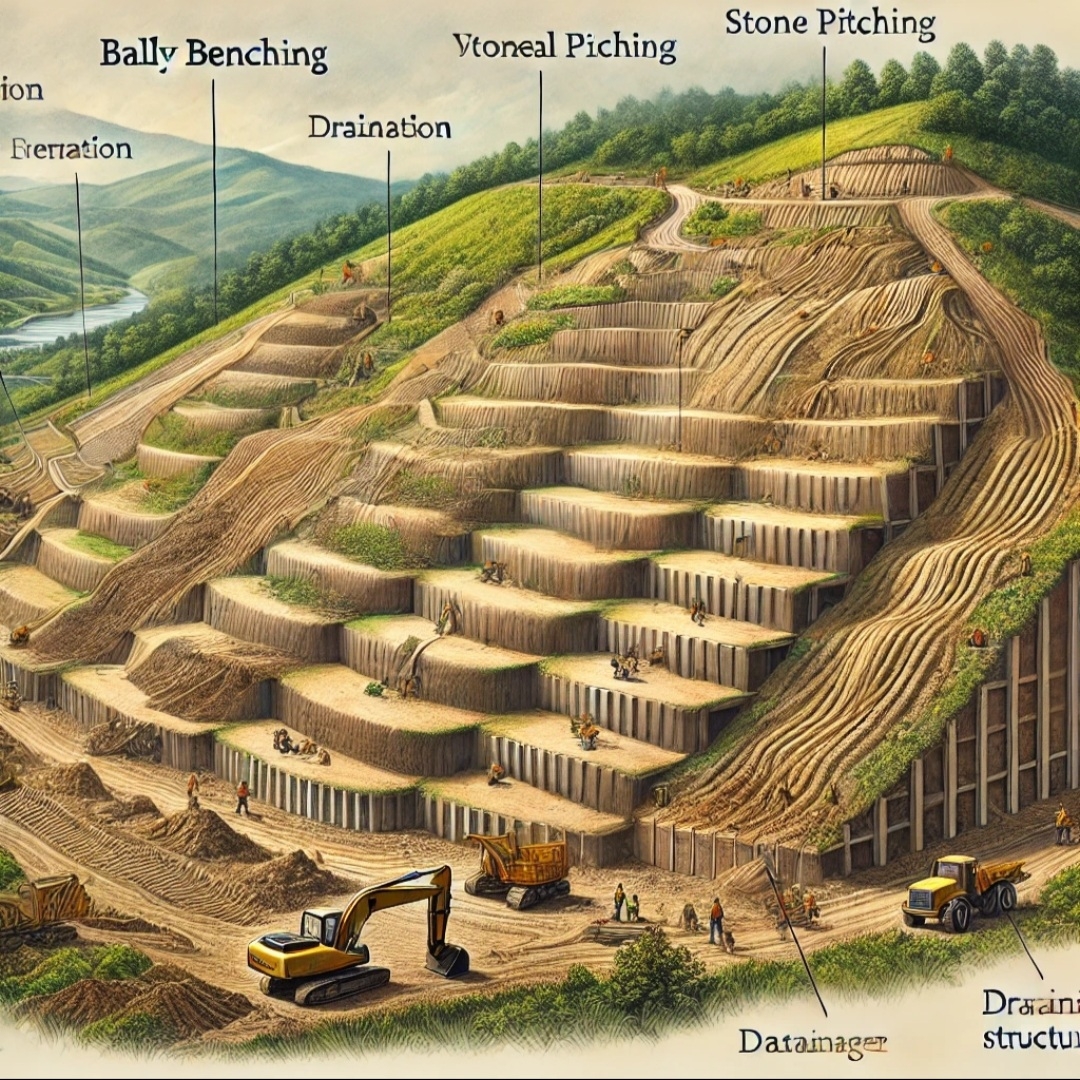

What is Bally Benching Process?

Sunday, January 19, 2025

125 किलोमीटर लंबी ऋषिकेश-कर्णप्रयाग रेल परियोजना

125-kilometer-long Rishikesh-Karnaprayag rail project

Kedarnath Forest Division for installing these advanced bio-digester toilets

Penalty imposed for RG Buildwell Engineers Limited

चमोली जनपद मुख्यालय गोपेश्वर में केंद्रीय विद्यालय का नया भवन

The newly constructed building of Kendriya Vidyalaya in Gopeshwar

The newly constructed building of Kendriya Vidyalaya in Gopeshwar, the district headquarters of Chamoli, has been completed. District Magistrate Sandeep Tiwari conducted an on-site inspection of the newly constructed school building on Friday. During the visit, the District Magistrate reviewed the classrooms, laboratories, canteen, toilets, safety railings for children, playground, drainage system, and other facilities in the school building. He instructed that a technical inspection committee be constituted to examine the provisions for electricity, water, and fire safety, and a report be submitted. Based on the committee's findings, any deficiencies observed should be rectified promptly, and the school building should be handed over without delay.

The District Magistrate also directed that operations at the new building be commenced at the earliest. Additionally, he inquired about the number of registered students and the staff of Kendriya Vidyalaya. Engineers Manoj Kumar and site engineer Santosh Singh from the implementing agency, C&DS UP Jal Nigam, informed that all approved construction work, including the school building, eight staff quarters, one principal's residence, a playground, boundary walls, and other facilities, has been completed on three acres of land at a cost of ₹30.29 crores.

Monday, September 2, 2024

Types of drawings in any construction project:

Thursday, June 8, 2023

दिल्ली सहारनपुर देहरादून एक्सप्रेसवे

Flexible Pavement, Construction of Road or Highway

California bearing Ratio Method

What do you understand by Water cement ratio? How the quantity of water affects the strength of a Concrete mix?

SHOTCRETING OF Slope Protection Work

Casting yard में Kerbstone की Precast कैसे किया जाता है? KC Drain Site पर कैसे बनाया जाता है?

Geometrics of hill Roads

औली टूरिस्ट प्लेस उत्तराखण्ड,औली टूरिस्ट प्लेस उत्तराखण्ड यात्रा गाइड 2021

Girder Launching Steel Composite Bridge |How to fix PTFE pot bearing of steel composite bridge

Defence Minister Shri Rajnath Singh today virtually inaugurated 125 major infrastructure projects across the country.

🇮🇳 A proud moment for the nation! Defence Minister Shri Rajnath Singh today virtually inaugurated 125 major infrastructure projects across...

-

Embedment length The length of embedded steel reireinforcement, 1 provided beyond a critical section. The fibre length also defines the e...

-

QUARRY OPERATIONS 1) INTRODUCTION Roads network, as a means of communication, plays a very important role in the life of a nation. The bu...